I'll explain the glass fusing process below. Please follow the links to see pendants, memorials, bowls, tiles, and other items that you can purchase now or that can inspire your ideas to collaborate with me on a project.

The Glass Fusing Process

Theory - The entire premise of fusing glass rests on the nature of glass as an amorphous substance (non-crystalline) with a known surface tension. Glass is a brittle solid material at room temperature, but when heated it softens and becomes liquid at known temperatures. The art of fusing glass is all about arranging and manipulating glass to take advantage of these properties while avoiding the attendant problems that can occur.

This image is taken through the porthole of my kiln when the glass is heating up, but not yet fusing. The orange color is due to the "color temperature" of the heat in the kiln.

Once the plan is clear and the glass is assembled, cutting the glass is usually the next step. Glass is "scored" rather than actually "cut." Once a proper score has been made, the right amount of pressure in the right place results in the score "running" through the glass, and the piece splits at the score. On the right, I'm using a pistol grip hand cutter, and below I'm using a strip cutting system. These are just some of the cutting tools available, although all have in common a diamond wheel rotating on the glass surface.

Step One in a glass fusing project is a lot of thinking about what one wants to create and the best way to go about it. What type of glass, what colors, etc. A lot of happy accidents can occur, but in general it is necessary to envision the final product so that the right steps can be taken to produce it and to avoid the many pitfalls that can derail the project.

Small deviations and fine changes of shape are dealt with using a glass grinder (below)

Depending on the design, lots of other steps in cutting, assembling, gluing, and other actions can occur. But for simplicity, let's say that the next thing that happens is that the pieces are assembled and placed on a prepared kiln shelf. The preparation of the kiln shelf involves use of a "separator" that keeps the fired glass from sticking to the kiln shelf when the firing is completed.

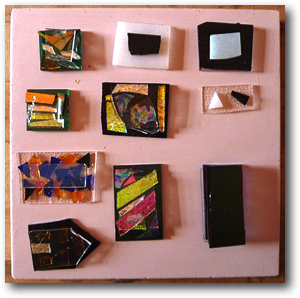

Below on the left is a kiln shelf with several pieces assembled and read to be fired. On the right is the result of the firing. Many of these pieces will be worked further and fired again before they are completed.

Below on the left is a kiln shelf with several pieces assembled and read to be fired. On the right is the result of the firing. Many of these pieces will be worked further and fired again before they are completed.